Description

Our UMC4000 blade control system is used on construction and land-leveling machinery or machinery blade attachments to automatically control the blade in earthmoving and grading applications. It could also be used on drainage, trenching or milling machinery. By the use of machine laser receivers, ultrasonic transducers or slope sensors a reference elevation will automatically be transferred to the cutting edge of the blade. The system is ready for integration of GNSS or TPS system using a digital terrain model as reference.

UMC4000 consists of a control unit and a control panel (MMI = man-machine-interface) with joystick and programmable functionality. The system controls up to 8 different hydraulic functions, no matter if tied to On/Off solenoid or proportional valves (PC or PV). Thus, UMC4000 features blade elevation control of up to three height cylinders (main, if there is, plus right and left) and automatic adjustment of both hydraulic side doors of the grading blade. In addition, our MMI steers other functionality such as control of three-point-hitch, hydraulic masts or folding the blade for road transportation, as an example. The UMC4000 is versatility at its best.

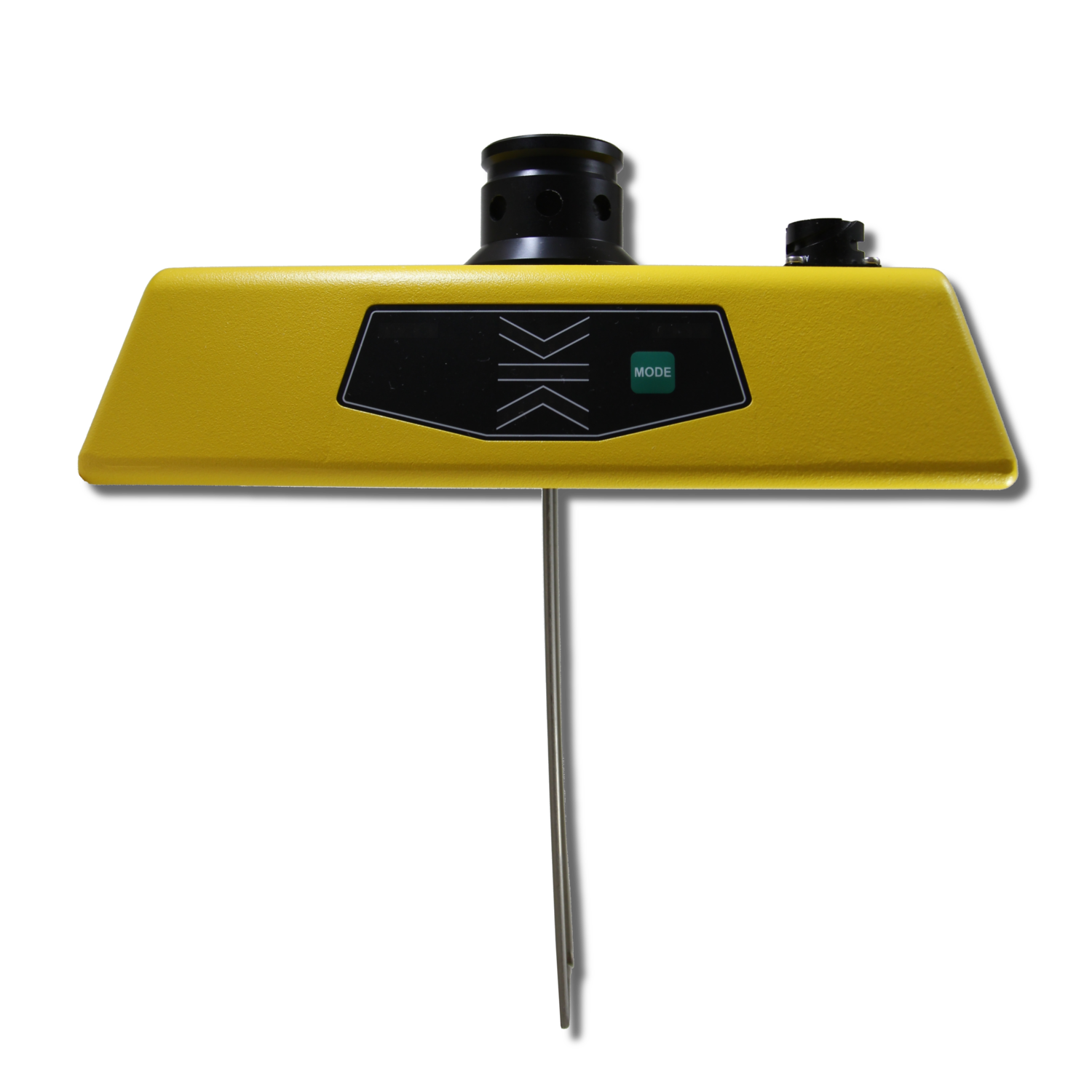

Technical data of the control panel

| Joystick: | Proportional, with 3 push button switches |

| Graphical display: | 128 x 64 px |

| LED displays: | Auto/Man (green/yellow) + Elevation R/L + Auto-Side-Door On/Off |

| Keypad: | On/Off/Setup + Auto/Man On/Off + Auto-Side-Selection Both/L/R + Offset Both/L/R + Sensor set-up SET + Auto-Side-Doors L/R + Slope Selection L/R + Slope inversion |

| Toggle switches: | Hydraulic blade side doors In/Out |

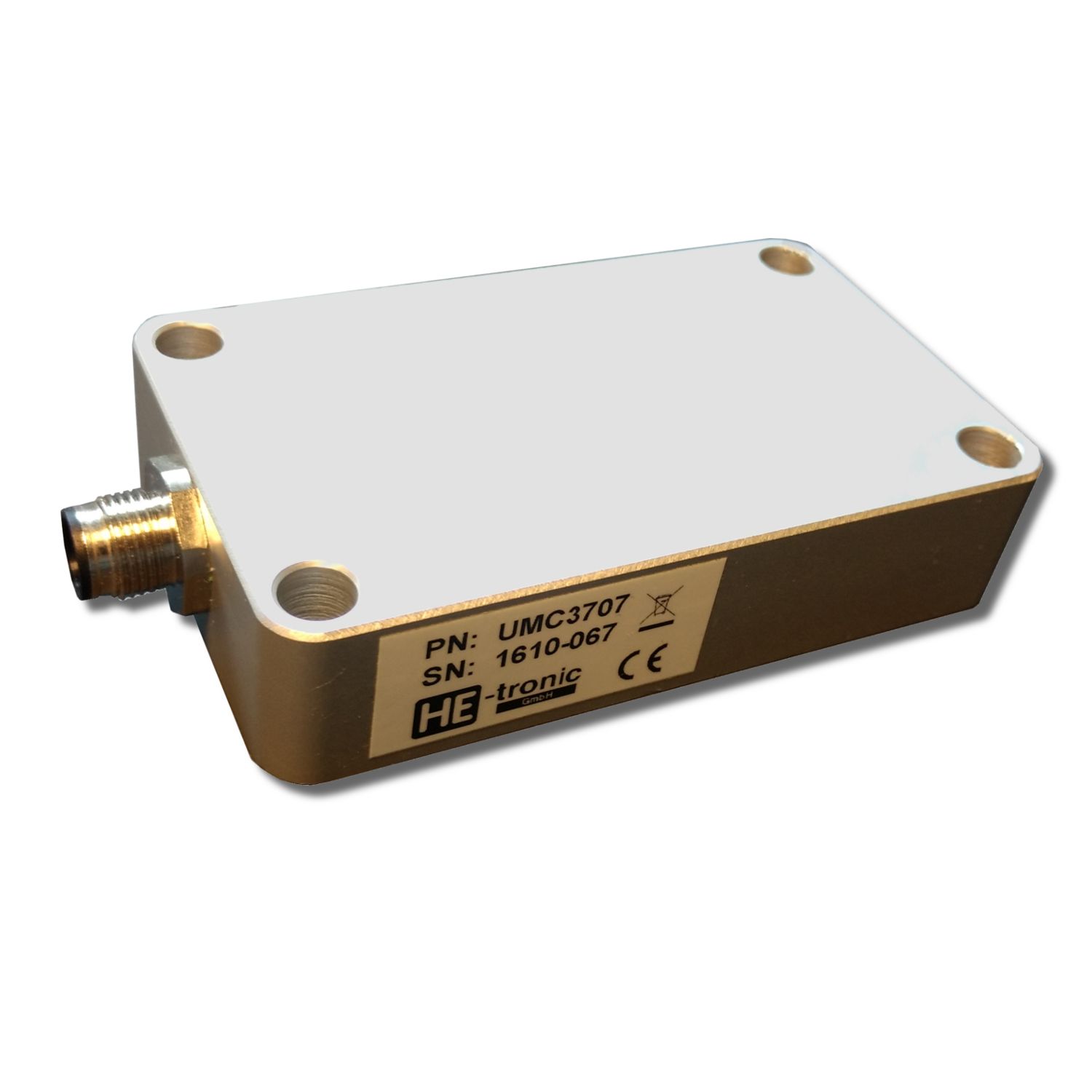

Technical data of the contoller unit

| Valve outputs: | 8 x PC/PT, or 6 x PV (each Raise/Lower) |

| Data input: | 2 x separated CAN or RS485 |

| 8 x Analogue, 0 ... 32 V | |

| Power supply: | 11 ... 28 V DC, max. 15 A, one extra power output |

| Protection degree: | IP65 (with plugs connected) |

Errors and changes accepted

Manufacturer: HE-Tronic GmbH, Am Esch 13, 26349 Jaderberg, Deutschland